Latest Blogs

Vet H20: purified water for autoclaves

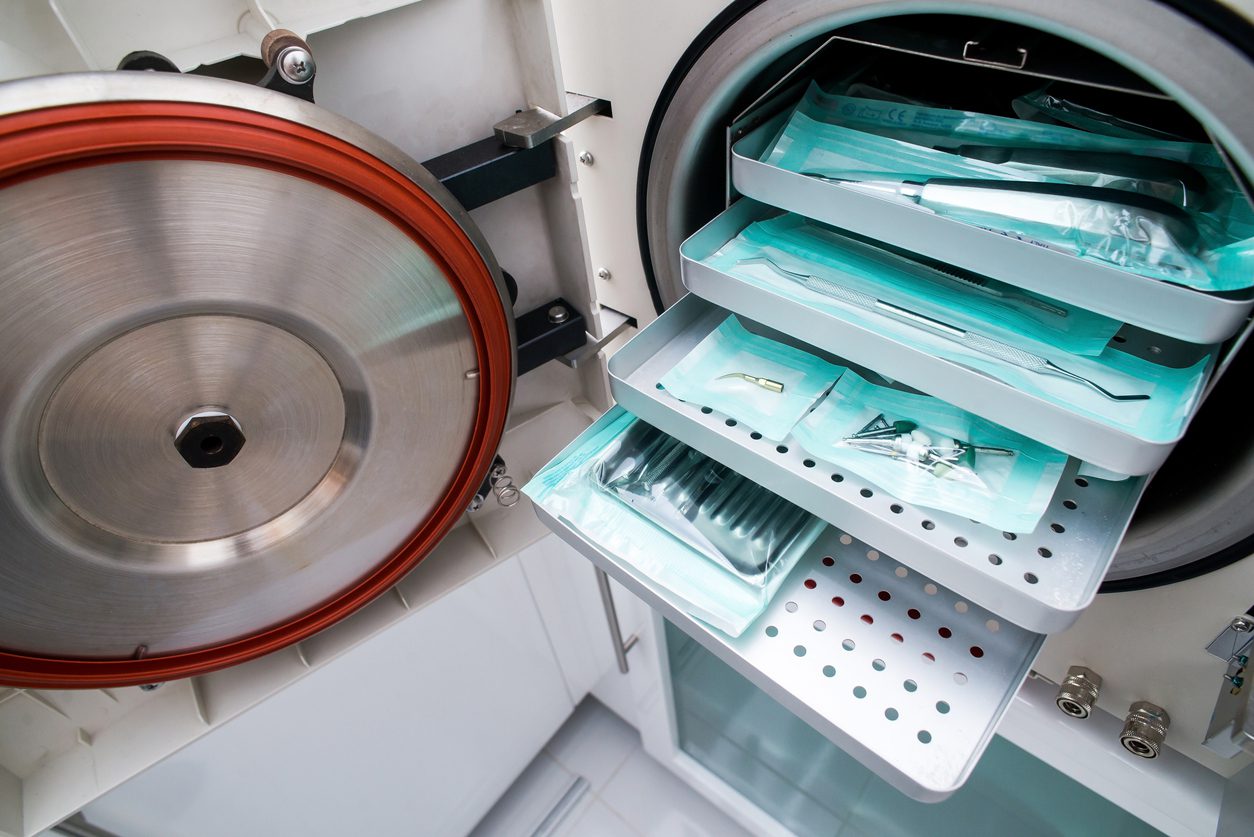

The importance of sterilisation

We are all very aware of the environmental pressures facing us today. As veterinary professionals, we are all compassionate and care about the world we live in. Sterility and hygiene play a key role in the outcome and success of our surgical cases. However, while our obvious priority when poised with a scalpel may be our patient, we also need to consider the wider impact of our work. Alongside the health and welfare of the animals directly under our care, we also have a duty of care to the sustainability of our work so it can continue without contributing to other global issues. Sterility and hygiene not only benefit the individual patient, but they also reduce the need for antimicrobials and thus reducing the pressures on antimicrobial resistance. So immediately, by using correctly autoclaved instruments, we are making a positive step towards sustainability. We also need to consider the environmental impact of our surgical procedures.

At Vet-Way, we supply consumables, which are used and then discarded. Consumables inherently create waste. The use of disposables is inevitable when trying to maintain sterility and good hygiene. At Vet-Way, we are committed to making the use of our consumables as environmentally sustainable as possible. The purified water we supply for use in your autoclaves and dental machines is manufactured using a purification method that is more efficient and uses less energy, than alternative purification methods used in the veterinary industry.

What is Vet-H20?

Our product Vet- H20 is purified water derived from a process called reverse osmosis. This process removes all the impurities that may damage your autoclave and make the sterilisation of your surgical instruments less effective. Autoclaves require purified water to operate, using tap water leaves deposits in the system that leave scale and shorten the life of your machine. For many years, the default has been to purchase distilled water for use in the autoclave. Distilled water is a type of purified water using a traditional method. For many years, the distillation process was the method used for the purification of water.

In simple terms, distillation is the process of heating water to a level where the pure water becomes steam, which is captured, and all the minerals, ions, and chemicals are left behind as residues. The steam is then cooled and this product is the purified water. This process requires a lot of energy for heating and cooling. As an example, to produce one litre of water requires approximately 1.65KW of energy and nine litres of water. Approximately 6.9kg/m3 of carbon dioxide is produced through the distillation process.

The process of reverse osmosis used for our Vet-H20 is much more energy-efficient. Reverse osmosis uses pressure instead of heat to purify water. Solids and other impurities are removed from the water by using high-pressure pumps to force water from a high solute concentrate to a low solute concentration through a semi-permeable membrane. The resulting water has a high level of purity. In comparison to traditional distillation, this process requires less than five litres of water to produce one litre of purified water, using only 0.1KW of energy. The carbon dioxide emissions from this process are also much lower at just 3.8kg/m3.

The British veterinary association and Vet Sustain provide a framework and support for veterinary practices to improve their impact on the environment. As a company, we want to help practices make this framework operational and are always looking for ways we can improve the sustainability of the products we supply. Changing from distilled water to Vet-H20 is one simple step you can make to become a greener practice.

If you would like to purchase our purified water solution, click here or get in touch with us on info@vet-way.com or +44 (0) 1904 607 600.